CLEAR VISION and COMFORT with STYLE

Colorpia International (M) Sdn Bhd was founded in 2012 and have since established itself as a professional color cosmetic contact lens manufacturer. Colorpia produces premium color contact lenses made with cast mold and implementing the patented PLUSIERUS process technology where capsulated pigments are embedded between coating layers, preventing pigments from having direct contact with the eyes.

Our main concern has always been the health and comfort of color lens wearers, as well as the quality of our products. Colorpia adheres to the highest quality standards and has obtained approval from GDPMD, GMP, FDA and the European CE Mark, ensuring a high standard of quality for all our products.

Colorpia’s unique lens designs and a wide range of color selection creates an endless possibilities for its wearers, natural to glamorous, day or night for any occasions, and satisfying even the most demanding fashionista.

Beyond just good looks, Colorpia high quality color cosmetic contact lenses provide wearers

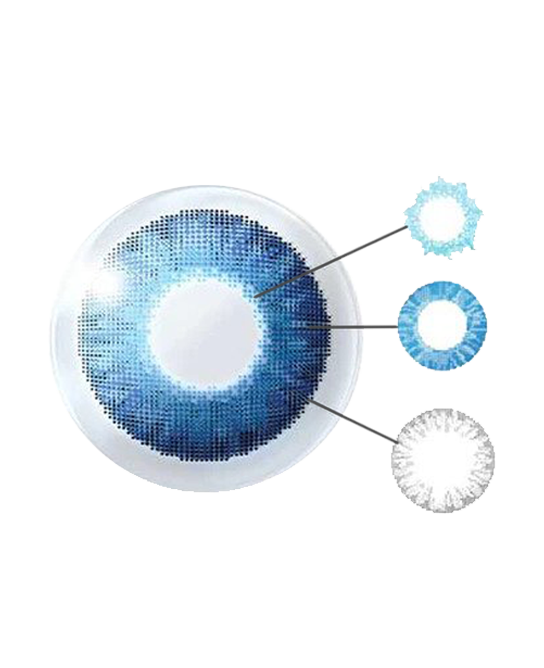

The sandwich coloring method for producing colored contact lenses involves layering a colored material between two layers of clear material, and then fusing them together. Here's a more detailed explanation of the process:

The sandwich coloring method used to produce colored contact lenses offers several benefits to wearers:

Copyright @ Colorpia. Designed By Asia Pacific Net (M) Sdn Bhd.